Filters

Type of Docks: Which One is the Best?

If you’ve just purchased property close to the water or are looking to revamp your current property, you’re probably considering building a dock. Docks are useful and valuable no matter where on the water you are situated.

If you’re ready to enjoy your own personal dock but find yourself baffled by the different types of boat docks out there, let the experts at EZ Dock lend you some advice. Our water experts and enthusiasts are here to help you choose the ideal dock that will let you spend less time on upkeep and more time in the water. Since 1991, we’ve matched boat owners with floating dock options that meet and exceed their unique personal watercraft (PWC) needs.

Read the full guide to docking choices or jump to a specific section:

- Determining Your Dock Needs

- Benefits of Owning Your Own Dock

- Types of Permanent Docks

- Types of Removable Docks

- Dock Materials

- Potential Dock Safety Hazards

- Docks Designed for Rough Water Conditions

- Choosing the Best Dock Material

Determining Your Dock Needs

You need to consider several different factors when determining your dock needs. There are numerous different types of docks and material choices. Where you place your dock is another important element, as things like tides or bottom conditions can help determine which type of dock to use for your waterfront area. While different docking systems and configurations offer their own benefits, certain structures will align with specific needs better than others.

Although there are assorted types of boat docks, they can be placed in one of two general categories — removable and permanent docks. Permanent dock structures are installed securely into the ground with the intent to remain there permanently. Removable docks are typically semipermanent with the option to expand, reconfigure or remove them as necessary. When choosing a dock style, the first step would be to decide on the location and ask yourself the following questions:

- How deep is the water, and what are the conditions like at the bottom?

- Should the dock be permanent, adjustable or removable?

- How many boats, kayaks or other PWCs will the dock need to accommodate simultaneously?

- Will the water level rising and falling limit the dock’s usage?

- Will the dock be exposed to any ice during the winter if the surface freezes?

- Does your area experience heavy boat traffic or frequent storms?

- How much are you willing to spend on building and maintaining your dock?

- Are you having the dock installed or are you looking for a dock option that’s DIY-friendly?

Whether installing a dock in a residential area or adding value to a commercial space, you’ll want to consider how your needs could change. For instance, owners of residential properties may choose to install removable docks so that future owners have the option of removing the structure. Similarly, owners of commercial establishments like marinas or restaurants may want to install removable docks to easily replace or repair dock sections or for the purpose of future expansion.

Benefits of Owning Your Own Dock

Whether you’re a homeowner or a business owner with property on a lake, river, oceanfront or harbor, building a dock can present a number of advantages. Some of the benefits of owning your own private dock include the following:

- Immediate access to water

- Added security with no slip or storage fees

- Opportunities for customized construction and accessories

- Increased property value

- Ability to use it for other leisure activities

If you enjoy spending time out on or near the water, there are numerous ways to use and benefit from having your own private dock — you just need to determine the best one for you!

Types of Permanent Docks

Permanent dock installation requires heavy equipment and intensive labor since they are installed on the floor of an ocean, lake or river. These types of docks work well in shallow but consistent water. If you’re thinking of building a permanent dock, these are your options:

1. Crib Docks

Crib docks are permanent and custom-built, made from wooden frames or crates called “cribs.” The cribs are placed at the bottom of the water, filled with large rocks and then covered with decking. While very stable, crib docks are typically expensive. They basically extend the shoreline and can affect the natural flow of water and disrupt wildlife. Some areas don’t allow crib docks because of this.

A crib dock should last for decades, which makes it an excellent docking structure for permanent applications. However, those who select this type of dock are trading convenience for stability. Crib docks are intended to be installed for long-term use, which means they cannot easily be removed or extended. Crib docks may also cause long-term environmental problems, like disrupting the water flow along the shoreline, affecting nearby wildlife and causing further issues if a flood were to occur.

2. Suspension Docks

Almost the opposite of crib docks, suspension docks hang over the water via cables and anchorage. These docks have a modern appearance and have much less of an impact on the environment compared to crib docks. Their interesting design may be visually appealing — however, due to the engineering required in their installation, suspension docks are very costly and time-consuming.

Much like crib docks, installing a suspension dock is not a decision that should be made until all factors have been considered. There are some drawbacks that suspension dock owners may not immediately anticipate. For instance, while floating dock structures can be removed during instances of severe weather, suspension docks are stationary and are forced to endure potentially damaging winds or water swells. If the dock is made from wood or aluminum, damaged pieces may cost more to replace than plastic materials.

3. Fixed Docks

Fixed docks are great in areas with choppy water. You can usually recognize them by their large attached structures, like gazebos. Fixed docks are one of the most stable platforms to walk on since they are built out of wood or concrete with attachments to the floor under the water.

These docks are best suited where water levels remain stable and consistent. If water levels rise too much, the dock could be submerged in water. If the levels dip too low, the dock ends up too high above the water, leaving getting on or off your boat quite a challenge.

4. Piling Docks

With piling docks, large wooden beams called pilings are inserted deep into the floor under the water. Then, the pilings are connected to the dock — typically by an attachment that contains hoops, rollers or both — which will then allow the dock to rise and fall with changing water levels while still maintaining its position in the water. Piling docks work well as fishing docks and for larger boats.

It’s essential to thoroughly plan out the construction of a piling dock, as success rests solely on its structural integrity. Any mistakes, incorrectly treated materials or cut corners could lead to expensive damage. For example, untreated wood could easily rot, whereas fiberglass is more durable. Pilings also need protection from destructive organisms and harmful UV rays. Although they can withstand strong currents, piling docks are expensive to build and maintain and don’t adjust to water level changes compared to a floating modular dock.

Types of Removable Docks

Removeable docks work best where the bottom of a body of water is too soft or deep for conventional dock attachments. There are several types of removable docks available, including the following:

1. Floating Modular Docks

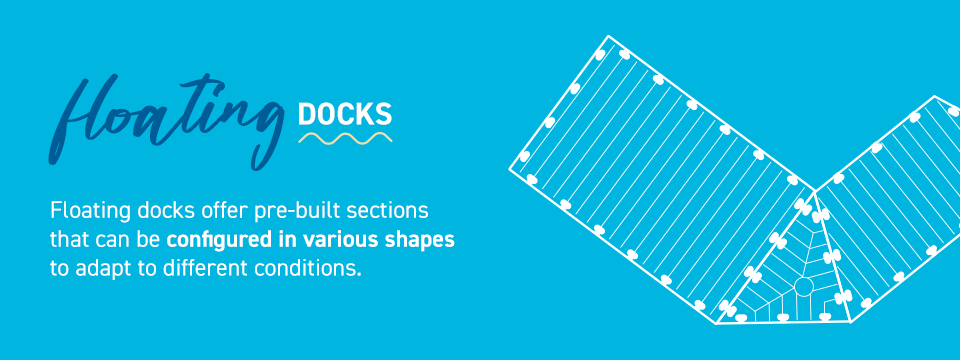

Floating docks are versatile platforms designed to stay on the surface of water, typically supported by airtight drums. They offer pre-built sections that can be configured in various shapes to adapt to different conditions. Unlike fixed docks, the purpose of all types of floating docks is to adjust to water levels, making them suitable for rivers, seas or lakes that cannot support permanent structures.

The practicality of floating modular dock systems surpasses other dock types. They often require fewer permits since they minimize sediment damage, and critical electrical systems attached to the dock surface remain above water levels. During severe weather or off-season periods, floating docks can be easily moved to safe storage locations and quickly reinstated when needed. In certain cases, a floating modular dock can even remain in the water throughout winter, provided there are minimal wind or water currents that could potentially damage the docks by pushing ice against them.

2. Pipe Docks

Pipe docks are built very much like piling docks but with aluminum frames and removable decking. They are easier to build and more cost-effective. However, pipe docks are less stable, which is why they only work well in shallow water and need to be removed in colder months to prevent damage to the pipes due to freezing. Pipe docks cause the least impact on the environment since their surfaces barely make contact with the land or water.

While floating modular dock structures can rise and fall with the water level, pipe docks are stationary, meaning they submerge easily underwater. It’s recommended that the dock is raised, lowered or relocated in regions where seasonal variations may significantly influence water level or cause the water to freeze over. Though this dock system is initially less expensive, ice and rough currents may damage the piping or surface. Owners should anticipate repairing or replacing the pipes or surface sections occasionally.

3. Lift-Up Docks

These docks are popular in cold areas where snow and ice have an impact on the environment. They usually have sturdy galvanized steel frames. Lift-up docks are attached to a winch that can be drawn up or even removed if necessary to protect it from any damage caused by ice. As convenient as they are, they can be quite expensive compared to other types of docks.

4. Rolling Docks

Combine the stability of piling docks with the flexibility of floating docks and you’ve got rolling docks. They’re made out of lightweight aluminum and come with a set of large plastic or rubber wheels that make installation and removal easy, provided there’s enough space to roll them up onto the share. Rolling docks are suited to both calm and choppy waters and can also accommodate most types of PWCs.

Even though these docks are versatile and easy for owners to install themselves, they’re not compatible with all shorelines. Rolling docks need large flat areas for storage, plus hard ground with no rocks.

Dock Materials

Choosing a dock involves much more than simply picking a style that meets your visual expectations. As described, there are many features of both fixed and floating docks that make each suitable for a particular application. The type of material used to construct the dock should be another critical consideration when designing your new or replacement dock. To make the best decision for your water-side structure, you should examine factors including initial cost, durability, upkeep, damage risks and environmental impact.

Thankfully, you have options when it comes to building both a floating and fixed dock. Wood, aluminum and plastic are three popular boat dock decking materials you’ll likely consider. Though all three can provide watercraft owners with a sturdy and reliable platform for launching watercraft, not all materials have similar benefits. The differences between the three impact everything from long-term operating and ownership costs and maintenance responsibilities to the way these materials may potentially cause harm to the environment and those who use the dock.

1. Wood Docks

Some may picture a traditional wooden dock for their property, and it’s easy to see why. For those who prefer a natural look, wood is aesthetically pleasing. However, though wood is a traditionally well-known boat dock decking material, it does have several drawbacks — including intensive upkeep, a variable life span and limited safety hazards. Other factors include:

- Cost: Prices for new wooden decking materials will vary depending on the actual type of wood used. Cedars and hardwoods fall under the more cost-effective range of the scale per square foot. Though many pressure-treated kinds of wood will also fall into that range, synthetic wood can also be expensive. However, if you have an existing older dock that doesn’t have structural damage, you will want to invest in upkeep and maintenance, as regularly restoring it to its former beauty will increase its longevity.

- Durability: Wood docks provide a natural look and a polished finish and could last a few years. However, they do need extensive staining, sanding and sealing to last. Still, compared to other materials, wood has the shortest life span and will cost you the most in fees and time to maintain.

- Upkeep: Painting and sealing pine or wooden docks is only a temporary solution. Continued exposure to fresh or salt water and rain will cause wood to eventually rot and degrade. Pressure-treated lumber may require constant monitoring and preventative maintenance to stop the wooden components from degrading and ruining the dock. A wood dock may also need to be refinished every two to three years.

- Potential damages: Termites aren’t the only threat to wood docks or docks with wood decking — many types of insects can damage untreated wood. Powerpost beetles could be attracted to the dock and decking, depending on the area you live in and nest in untreated wood — which may not begin to show signs of damage until the beetles emerge. Carpenter ants may nest in wood that’s been damaged and begin to tunnel through the structure. Carpenter bees may also bore into wood to lay their eggs.

- Repairs: Along with becoming a safety hazard, dry-rotted wood replacements could cost you hundreds of dollars. Piling or pipe replacements could cost more, up to as much as $1,600 per piece! However, if you discover minimal rotting or small pitted holes, you can likely repair these areas yourself with wood filler. Other simple fixes to older wooden docks that don’t have major structural damage include fixing loose boards, removing stains and discolorations and replacing loose nails and cracked boards.

- Environmental considerations: Wood is a 100% renewable resource and produces less air and water pollution than some other dock options. However, pressure-treated wood, which is used for dock construction in freshwater and saltwater areas, has the potential to contaminate the water. Because the wood-treating process uses chemicals, all manufacturers of treated wood have to abide by the Environmental Protection Agency (EPA) minimum retention-rate standards.

- Configuration ability: Permanent wooden docks, such as piling docks or crib docks, are not easily removed. Extending or reconfiguring a piling or crib dock would require significant work. A crib dock is typically a customized structure and would require a customized solution to extend or redesign it to your needs. You should also consider any rules and regulations that your area has regarding the installation of dock additions.

- How long they last: A well-maintained wooden dock made with pressure-treated lumber could last around 10 years. However, even with regular maintenance, there’s always a risk of rotting, warping, splitting or splintering. Nails in the wood may also come dislodged over time.

2. Aluminum Docks

While your first thought may be traditional wooden docks when considering your options for decking materials, aluminum decking is another option you can weigh up. Assembled with interlocking edges, aluminum decking planks create a watertight and gapless seal. Some other considerations are:

- Cost: Typically, aluminum docks are pre-built by the manufacturers and may have heftier initial costs. As a result, it is typically one of the more expensive materials you can choose for your dock.

- Durability: Unlike wood, which is susceptible to environmental impacts, aluminum is resistant to scratches and weather forces. Aluminum is also three times stronger than wood while being as much as four times lighter.

- Upkeep: Even though aluminum doesn’t rust, it will corrode, which could affect the dock’s structural integrity. Aluminum becomes dull from corrosion and can become encrusted with everything from calcium and lime to hard-water stains. You’ll need to frequently spray saltwater docks down with plain water to prevent salt corrosion. To clean spots contaminated with hazardous substances, grime or algae, mix water and baking soda into a paste and scrub the areas with steel wool or a wire brush. Then, you’ll want to pressure wash the entire dock.

- Potential damages: Thankfully, aluminum docks are strong enough to resist damage from impact with watercraft. However, as with any vessel that makes contact with a sizeable object, an aluminum dock could cause damage to a boat.

- Repairs: Because aluminum decking will not rot, attract damaging pests or grow mold, repairs are usually minimal.

- Environmental considerations: Though the mining process and refinement of ore require a lot of energy, aluminum is heavily recycled. You can reuse uncontaminated aluminum almost indefinitely.

- Configuration ability: Because aluminum docks are typically manufactured in sections for installation, they can be added onto or reconfigured. While permanent structures like wood piling docks cannot be removed easily, aluminum docks can usually be folded and stored when not in use during the winter or seasons with heavy storms.

- How long they last: Lasting the longest of most materials, aluminum decking should stand the test of time.

3. Plastic Docks

Those looking for a durable, innovative floating docking system should consider plastic decking. This type of dock material is easy to install and can cater to budgets of all kinds. It is also a great option if you want the durability and longevity of aluminum docks but without the high price tag.

While permanent wooden docks may have once been the traditional docking system, they’re no longer the most practical option. A plastic floating modular dock tends to offer more benefits and fewer drawbacks than wooden and metal permanent docks combined, including the following:

- Cost: Fixed docks made from wood or aluminum may cost more in one’s overall ownership, but resin or plastic floating docks can save you money in the long run. Their ability to be reconfigured instantly allows you to update your dock as your needs change. They’re also portable, which means your single docking system investment can move with you wherever you go.

- Durability: Resin decking and plastic docks are made of durable dock surface materials and designed for maximum durability to give you more time on the water. In both freshwater and saltwater environments, polyethylene docks won’t rot or splinter like wooden docks. You also don’t have to worry about replacing an entire structure should one part of it incur damage. If a resin or plastic dock section is damaged, it can be easily replaced. There is no worry about damaged posts, pipes or pilings either.

- Upkeep: Wooden docks require regular maintenance, and while aluminum docks may not need as much upkeep, they still require an attentive eye for rust, mold or other unfavorable occurrences. Plastic decks are much easier to maintain. Clearing the deck with a simple sweep can help the surface retain its beauty. You can clean it with soap and water and remove stains with deck cleaners and household degreasing agents.

- Potential damages: Floating modular plastic docks can help cause less damage to boats left in the water during harsh weather conditions or hurricanes. Unlike permanent docks that are stationary, floating modular docks can rise and fall with a surge that will keep the stress on dock lines at a minimum. When it comes to horizontal movement, a good set of fenders is likely the best protection to reduce damage to the boat.

- Repairs: With durable floating plastic dock designs, your initial investment lasts much longer. In fact, many plastic decks come with warranties that protect against certain damages. For example, EZ Dock products and components are covered under a limited warranty. That means that any cracks, leaks, breakage and ultraviolet deterioration due to workmanship or material flaws are covered during the warranty period. All hardware and accessories are covered for the first year as well.

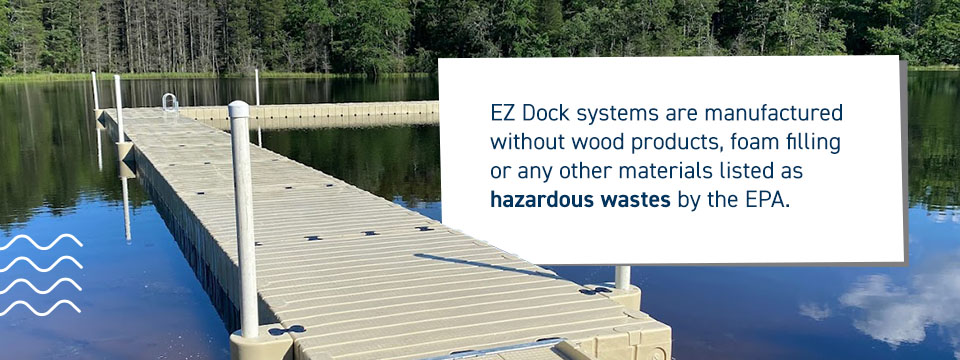

- Environmental considerations: While certain chemical wood treatments or metals could contaminate the water, eco-friendly EZ Dock systems are made from polyethylene and molded rubber couplers that are recyclable and do not harm the environment. They are manufactured without wood products, foam filling or any other materials listed as hazardous wastes by the EPA. Up to 90% of the product is made with pre- or post-consumer waste recycled rubber and does not release any contaminants when damaged.

- Configuration ability: Fixed wooden or aluminum docks may have some advantages, but one significant drawback is that they are quite costly and labor-intensive to expand, reconfigure or remove. Floating docks, such as those made by EZ Dock, can be easily removed when not in use. They can also be expanded or redesigned to adapt to multiple waterfronts and are available in customizable floating dock sections in a variety of configurations to cater to every need.

- How long they last: Any large purchase you make should be an investment that you can rely on to last for years. Your dock should be structurally strong enough to maintain its integrity under normal circumstances and be able to endure any severe weather that might threaten its security. Certain types of fixed wooden or metal docks may not be constructed to survive heavy storms, but durable plastic docks are made to last. EZ Dock is designed to withstand many environmental challenges, including most low- to mid-category hurricanes.

Potential Dock Safety Hazards

There should always be a concern for safety when creating and operating any dock. Since people typically remove their shoes for water activities, most people using your dock are likely to be barefoot. With the risk of splintering or hot surface temperatures, you’ll need to keep in mind how the dock material can injure users with bare feet. Heat can make an aluminum dock rise in temperature, which could potentially burn the feet or hands of those who use it.

This characteristic makes choosing a wooden dock surface material preferable to metal, although darker wood colors absorb and pull more heat deep into the board. However, one hazard of wooden docks is the threat of splintering or rotting over time. Even treated surfaces can begin to degrade and show signs of damage as water and bacteria take their toll.

You should also consider how moisture and precipitation can result in slick dock surfaces. Regardless of the time of year, bad weather can create slippery conditions. If people are using your dock to enter and exit the water, there is potential for water to sit on the dock surface. If left untreated or uncleaned, wooden docks can be slick when wet and aluminum docks can quickly become slippery.

Also, wood expands as it absorbs moisture and contracts as it dries out. This process can cause the wood to splinter even more, and these splinters can carry bacteria that cause infection. To help minimize the chances of catching a splinter on your deck, you can sand down any split boards or large splinters that you see.

Plastic floating modular docks have an immediate advantage in safety, helping to eliminate most of the potential hazards inherent to wooden and metal docks. The surface of a polyethylene dock is slip-resistant and won’t splinter, enabling everyone to enjoy their deck freely without the worry of injuring bare feet. It also stays cool to help protect bare feet.

Docks Designed for Rough Water Conditions

One of the main forces of nature that docks have to deal with is rough water conditions. These conditions can be the result of high winds, severe storms, hurricanes and even tornadoes. Whatever type of weather causes the choppy water, one thing is certain — your dock is going to take a beating.

While traditional wooden docks may survive a couple of severe storms, before long, they’re going to start falling apart. Nails and screws will start to poke out, boards will loosen and the wood’s protective finish will wear down. Sooner than later, a wooden dock will decompose from the rough water conditions.

If you’re looking for dock ideas for rough water, a plastic floating modular dock is your best choice. They’re the best floating dock design for many reasons, including the ability to withstand turbulent weather conditions and violent waves. Plastic floating docks for rough water will survive storm after storm, so you can bunker down with confidence, knowing your dock will be fine when the storm subsides.

Choosing the Best Dock Material

Whether you’re installing a new dock or remodeling an existing deck, chances are that you want a completed project that doesn’t require constant maintenance or repairs. High-quality materials that are durable and safe are important, but you also shouldn’t have to sacrifice appearance to retain benefits. Before you decide on a decking material, you should compare all options to determine the immediate and long-term benefits and drawbacks of each. The best dock material will be a low-maintenance, barefoot-friendly surface that can endure years of weathering and use.

Aluminum and wooden docks do feature a handful of benefits, but plastic floating modular docks are by far the most advantageous waterfront solutions. Both initial and overall costs for plastic decks are lower than other docking alternatives, which helps you feel secure in your investment. They’re also easy to maintain, requiring limited upkeep in both fresh and saltwater environments. When shopping for a plastic dock, you should look for one that features a slip-resistant, eco-friendly surface that can be reconfigured, added on to or replaced when needed.

If you decide on a floating plastic dock, there’s no better option than EZ Dock — the ultimate waterfront solution. We are one of the top floating modular dock manufacturers in the world and have helped our customers design the perfect docking solutions for their homes, marinas, resorts, and industrial or government facilities. Lakeside, riverside and oceanside — wherever you need a dock, EZ Dock has you covered.

Our pioneering design uses recycled rubber couplings that allow each piece of the dock to move independently to keep the entire structure intact during the heaviest and harshest weather. These polyethylene docks are effortless to maintain in every environment. You’ll never need to repaint faded portions, replace rotted sections or repair splintered boards. Instead, our floating modular docks are designed to decrease time spent on maintenance while maximizing your time on the water.

EZ Dock Has the Floating Modular Dock to Meet Your Needs

Just starting the dock research process? Check out our guide on getting started to walk through additional considerations and get frequently asked questions answered. With competitive pricing and the ability to customize, EZ Dock will enhance your outdoor experience like never before. We offer various docking systems to suit your needs, including floating docks, ports, launches for kayaks and canoes, and lifts. We even offer add-ons, like railings, dock accessories and walkways, to help you achieve the exact dock experience you want to create.

If you are ready for more information or would like an easy quote, contact EZ Dock today. We can help you build a high-quality customized dock that is designed to both outlast and outperform wood and aluminum decks.